CNC Machining Non-standard Stainless Steel Parts

اسم العلامة التجارية: دقة الشمس يي

شهادة: ISO90001,ISO13485

أقل كمية ممكن طلبها: قطعة واحدة

شروط الدفع: خطاب الاعتماد, تي/تي

مكان المنشأ: قوانغدونغ, الصين

سعر: الاقتباس كما هو مطلوب

- وصف

- سؤال

وصف

Introduction

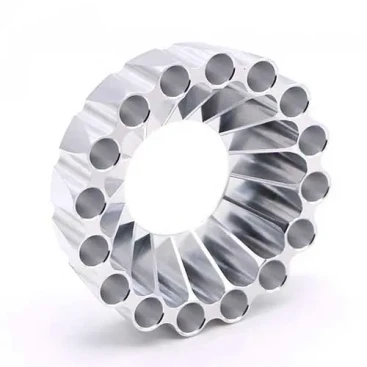

منتج: Non-standard Stainless Steel Parts

مادة: الفولاذ المقاوم للصدأ

Minimum wall thickness: customized

Machinable threaded hole diameter: customized

Processing trade form: according to the sample processing, according to the drawing processing

Machinable thread depth: customized

Surface treatment process: ساندبلاستيد, مصقول, anodized, يتأكسد, plated, brushed, sanded, مصقول

Country/Region of Origin: الصين

Whether to support customized tolerance: support customized tolerance

Sampling cycle: 4-7 أيام

Processing cycle: 4-7 أيام

Dimensional accuracy: Non-standard can be customized

Maximum processing size: customized

Factory Location: قوانغدونغ, الصين

مواد قابلة للمعالجة: stainless steel, iron, plastic, red copper, bronze, brass, aluminum

Machining type: machining center, computer gong processing, aluminum CNC processing, مخرطة CNC

Application of machined parts: robotics, الفضاء الجوي, automotive industry, consumer goods, معدات طبية

SUN-YEE TECH Non-standard Stainless Steel Parts CNC Machining Advantage

- CNC machining of precision stainless steel parts is extremely high precision and has stable machining quality. SUN-YEE TECH has CNC machining centers with high machining accuracy and stable machining quality. At present, our processing field covers automotive precision parts, automation equipment components and other fields. The accuracy of the processed products can be as high as ±0.01mm, which has been recognized by many enterprises!

- When changing the CNC machining of precision stainless steel parts, it is usually only necessary to change the computer’s CNC program, which can save production preparation time. For example, SUN-YEE TECH has a special CNC program storage device for precision technology. When changing the CNC program for machining stainless steel parts, we have the advantage of saving the production preparation time!

- CNC machine itself, high precision, rigidity, can choose favorable processing dosage, high productivity, than the general efficiency of ordinary machine tools 3 to 5 times more. And the high degree of automation of machine tools can reduce the labor intensity of manual labor. In general, CNC machining using short cutting tools is the main feature of precision stainless steel parts. Short cutting tools will significantly reduce tool deviation, obtain good surface quality, avoid rework, and thus shorten the processing time of stainless steel.