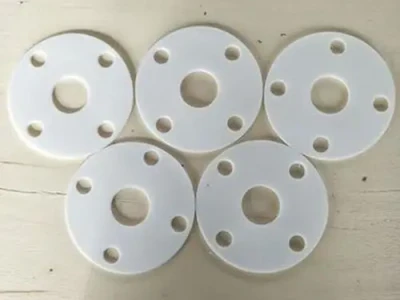

Characteristics of Teflon materials

Teflon materials introduction Teflon materials is the trademark name of polytetrafluoroethylene (PTFE), commonly known as "plastic king". And PTFE is a synthetic fluoropolymer of tetrafluoroethylene. In PTFE, each carbon atom is covalently bonded to two fluorine atoms and shares two other covalent bonds with neighboring carbon atoms. This structure forms a linear polymer in which all free bonds on each carbon...