ABS Plastic Parts Desktop Threading Hole

Brand Name: Sun-Yee Precision

Certification: ISO90001,ISO13485

Minimum Order Quantity: One piece

Payment Terms: L/C, T/T

Place of Origin: GuangDong, Chine

Price: Quotation as required

- Description

- Inquiry

Description

ABS Plastic Parts Introduction

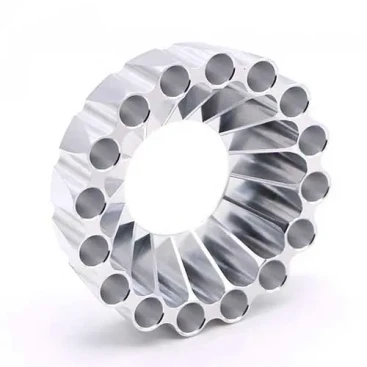

Produit: ABS plastic parts

Application: Desktop Storage

Matériel: ABS

Size: Customized

Black,White,Silver,Color Customization

Advantages

1, This plastic raw material is a very good dyeing characteristics. Commonly speaking, it can be quickly stained with color.

2, This kind of plastic material is hard material. Because of this characteristic, it is widely used in many aspects.

3, ABS is not easy to burn. Donc, compared with other materials, if you use this material, it will provide a safe environment.

4, ABS is also very good in terms of impact resistance

5, The surface of ABS material is full of luster.

Production process of plastic products

1、Materials

The first step in making plastics is to prepare the materials. In addition to polyethylene, polypropylene and other polymers, it is also necessary to prepare auxiliary materials. These include plasticizers, colorants, stabilizers, and lubricants. The addition of these auxiliary materials can not only increase the performance of the plastic to a certain extent, but also reduce the cost of making plastic.

2、Molding

This step is through a variety of processing techniques to plastic raw materials into plastic blanks. In the first step, there are many plastic molding process can choose. The choice of processing technology needs to be combined with the characteristics of the plastic raw materials, some of the characteristics of the final plastic product, the shape and size of the plastic starting to consider.

3、Machining

This step is an auxiliary stage before the final molding. In the mechanical processing also need to make some adjustments.

4. Joining

It is to join different plastic parts together by welding or bonding. Among them, welding has friction welding, high-frequency welding, hot melt welding, hot air welding and ultrasonic welding. And bonding is mainly accomplished with the help of adhesive.

5、Finishing

Through some means to increase the beauty of the plastic products. For example, the surface of plastic products for grinding, polishing and other operations. Or draw some patterns and designs on the surface of plastic products.

6、Assembly

Is the last step, mainly will get some individual plastic products components combined together to get the plastic parts.