Flashlight front cover CNC machining

Brand Name: Sun-Yee Precision

Certification: ISO90001,ISO13485

Minimum Order Quantity: One piece

Payment Terms: L/C, T/T

Place of Origin: GuangDong, Cina

Price: Quotation as required

- Description

- Inquiry

Description

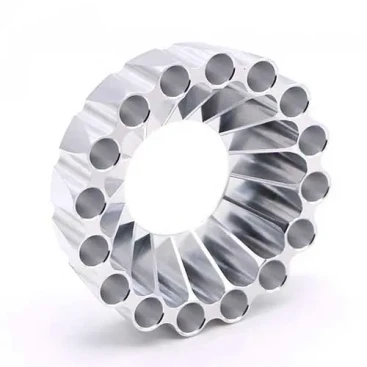

Flashlight Front Cover Introduction

Prodotto: Flashlight front cover

Material: Aluminum alloy, rame, titanium alloy, stainless steel, eccetera. are optional

Machining type: CNC machining center

Machining Precision: Finishing

Maximum diameter: 1000 (mm)

Maximum length: 500 (mm)

Product Use: Accessories for customized flashlights

Advantages:

Fine selection of materials. Smooth surface, high hardness and toughness, long service time

Structural stability. Polishing process, smooth surface texture highlights, beautiful appearance

Precision processing. According to the documents you provide, we have a team to produce, the size of the standard

Casting fine products. We adhere to the concept of quality first, carefully processing each product!

Flashlight front cover case:

How to choose the metal material?

- Aluminum: Aluminum alloy is light and soft, good strength, not easy to be corroded, good processing performance. Widely used in airplanes, automobiles, industrial appliances, eccetera.

- Brass: brass has good mechanical properties, good cutting, easy to braze and weld, corrosion resistance, but prone to corrosion rupture. Can be used for parts subject to large loads.

- Stainless steel: not easy to oxidize, not easy to corrode, can withstand high temperatures, widely used in industrial buildings, decoration, some shallow stretching products.

SUN-YEE TECH is a professional processing of various types of copper and aluminum hardware metal parts factory, currently has a CNC lathe, turning and milling composite, CNC computer (three-axis, four-axis, five-axis) a variety of measuring equipment, etc., the main processing of products are: medical parts, aerospace parts, aluminum flashlight shell, beauty salon equipment products, electric toothbrushes, skipping rope handle, grinding pen, car charger shell, smart watches hardware Electronic hardware, aluminum alloy customization, automotive parts, pneumatic parts, sports equipment parts, cell phone parts, Bluetooth stereo, camera flashlight, stereo shell, grinding machine parts, camera parts, toys, hardware and other types of hardware (rame, Lega di alluminio, stainless steel, iron, steel, POM, zinc alloy). Welcome to inquire