What damage is avoided during cutting during CNC 4-axis machining?

CNC 4-axis machining, the damage to be avoided in the cutting process mainly includes tool breakage and workpiece damage.

For tool breakage in the CNC 4-axis machining, the following measures can take to prevent:

Reasonable selection of tool materials and grades, to ensure that the tool has a certain degree of hardness and wear resistance at the same time, but also has the necessary toughness.

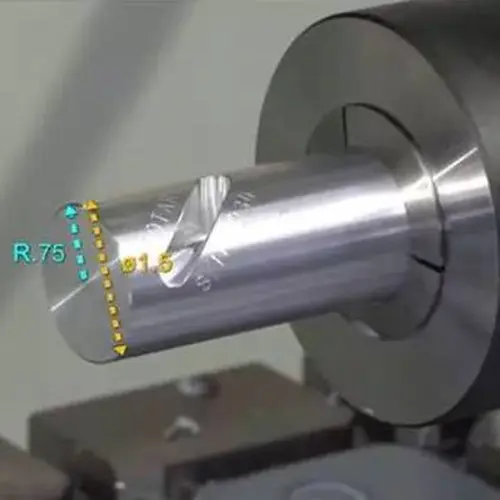

Adjust the geometric parameters of the tool, including the front and rear angles, main and vice-deviation angles, edge inclination, etc., to ensure that the cutting edge and tip have better strength. Grinding negative chamfer on the cutting edge can effectively prevent chipping.

Ensure the quality of welding and sharpening to avoid various defects brought about by poor welding and sharpening. For the tools used in key processes, their faces should ground to improve the surface quality, and check for cracks.

Reasonable selection of cutting dosage, avoid excessive cutting force and high cutting temperature to prevent tool breakage.

As far as possible to ensure that the CNC machining process system has good rigidity, reduce vibration.

Adopt correct operation method, try to make the tool not to bear or less bear the sudden changeable load.

In order to prevent damage to the workpiece, the following points need to note:

During the CNC machining process, the stability of the material should ensure to avoid any movement or vibration of the material. At the same time, the surface of the material should adequately treat to ensure that its surface is smooth, uniform, and will not affect the use of the tool.

When designing the workpiece, some principles should follow to minimize the cutting force and heat generation. Such as the use of smaller dimensions, avoiding sharp angles or too deep machining, and reducing the cutting volume and cutting speed and other measures.

During the machining process, should pay attention to the location and size of the machined parts for self-checking, checking whether the process is correct, whether the dimensions of the workpiece position to the reference edge are in accordance with the requirements of the drawings and so on, in order to ensure the machining accuracy and quality.