CNC加工銅精密部品

ブランド名: Sun-Yee Tech

認証: ISO90001,ISO13485

最低注文数量: ワンピース

支払い条件: 信用状, T/T

原産地: 広東省, 中国

価格: 必要に応じて見積もり

- 説明

- 問い合わせ

説明

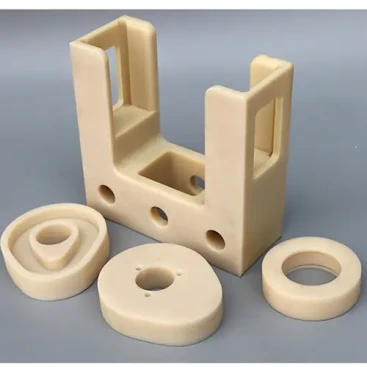

CNC machining copper parts introduction

Products: CNC machining copper parts

Service: OEM/ODM

許容範囲: ±0.01mm

Surface Treatment: Powder coating, hot galvanized, painting, 研磨, brushing ,chrome/zinc/nickel plating,surface passivation, 等

Samples: Accept

材料: brass

Customize Service: Yes

Package: Carton/ plywood packing

Products certification: ISO9001:2008

特徴

Copper, has good thermal conductivity, electrical conductivity corrosion resistance and welding properties. Low strength, excellent plasticity, widely used in electrical, thermal conductivity and corrosion-resistant devices. Industrial pure brass grade T1, T2, T3, T4 four, the larger the serial number, the lower the purity. Pure copper is mainly use for both thermal conductivity and corrosion resistance requirements of the structure, such as electrical appliances, electric motors.

Machining process

Copper is a versatile metal with good electrical conductivity. The process of producing CNC brass parts typically involves the following steps:

1. Design: A detailed 3D model of the required copper part is created using CAD (Computer Aided Design) software. This model will serve as the basis for the CNC machining process.

2. Material Selection: Select the right type of copper for the specific application. Brass is widely used for its excellent machinability and desirable properties. 3.

3. CNC Programming: Converts the 3D CAD model into CNC machine instructions. This programming step includes specifying toolpaths, depth of cut, speeds and feeds to accurately machine brass parts.

4. Machine Setup: Prepares the CNC machine for the machining process. This includes installing the proper cutting tools, securing the copper material, and setting the necessary machine parameters.

5. Machining: CNC machines use computer-controlled motion to remove material from brass workpieces according to programmed instructions. This process typically includes milling, drilling and turning operations.

6. Finishing: After the initial machining is completed, other finishing operations may be required to achieve the desired surface finish. This may include processes such as polishing, debur.