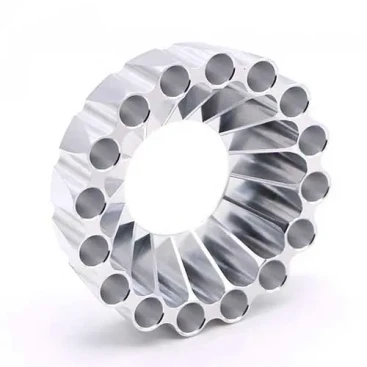

Precision CNC Copper Parts Machining

ブランド名: スンイー・プレシジョン

認証: ISO90001,ISO13485

最低注文数量: ワンピース

支払い条件: 信用状, T/T

原産地: 広東省, 中国

価格: 必要に応じて見積もり

- 説明

- 問い合わせ

説明

製品: Copper Parts Machining

Machining type: CNC machining

Machining Precision: Finishing

Processing material: 銅, copper alloy

Maximum diameter: 200 (mm)

Maximum length: 800 (mm)

許容範囲: 0.01mm

Surface roughness: Pa1.6

Copper Parts Machining Case:

Copper in the processing industry

Pure Copper

Pure copper carries an aura of purity and excellence that is hard to match. Oxygen-free copper, for example, is pure, contains very little oxygen and is known for its high electrical conductivity. There is also electrolytic copper, especially the C11000 grade. Its high conductivity (up to 100% iCS) makes it ideally suited for applications requiring higher conductivity.

Common Copper Alloys

Copper becomes stronger when it is alloyed with elements such as zinc, tin, aluminum, silicon and nickel. These alloying elements improve the machinability of copper, paving the way for high-speed machining processes. Consider the alloy 110 銅, which is often easier to machine than pure copper, giving it an advantage in manufacturing.

Specialty Copper Alloys

Specialty copper alloys are the result of careful design and have been developed to meet the needs of specific industries. They are highly valued for their unique corrosion resistance, thermal and electrical conductivity. Precision copper parts play an important role in applications such as valves and hydraulic piping due to their superior corrosion resistance and excellent thermal conductivity.

Key considerations when CNC machining

- Wall thickness

- Tolerance minimization

- Control of dimensions

- Avoid complex features: large openings, small radii

SUN-YEE TECH specialize in the non-standard hardware precision parts manufacturing

例えば, medical parts, aerospace parts, automotive parts, machinery parts, electronic parts, daily life hardware, 等. For more information, please contact SUN-YEE TECH.