3D printed model car parts / 3D printed auto parts

브랜드 이름: 선이정밀

인증: ISO90001,ISO13485

최소 주문 수량: 원피스

지불 조건: 신용장, 티/티

원산지: 광동, 중국

가격: 필요에 따라 견적

- 설명

- 문의

설명

3D printed model car parts / 3D printed auto parts

The use of 3D printed model car parts is increasing.

Automotive Parts and Accessories Industry Requirements:

1. Reduce development cycle time

2. Manufacture complex parts

3. Reduce costs

Problems that 3D printing can solve

1. from conceptual models to functional prototypes, which can be used to complete testing and design verification;

2. flexible manufacturing, especially suitable for complex components, complex pipes and thin-walled parts;

3. without any additional tools, no need for casting, die-casting, shorten development time and greatly reduce development costs.

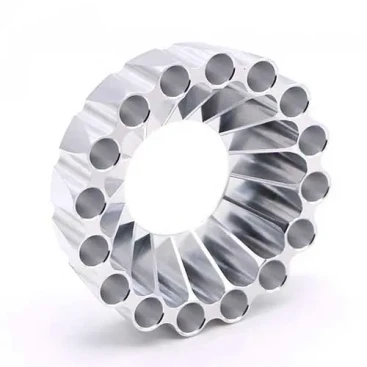

3D printed model car parts case:

Functional parts manufacturing

In order to prevent accidents caused by fuel leakage, it is necessary to ensure that the spacing between each injector support is equal. If the traditional milling process is used to produce, firstly, the processing difficulty is large, requiring five-axis CNC milling machine to process out. Secondly, the amount of milling is large, the material utilization rate is not high. The use of 3D printing technology can not only improve the utilization rate of the material, but also to achieve the production requirements of complex structures after lightweight design.

Lightweight Manufacturin

Automotive weight reduction is important for reducing fuel consumption and increasing handling and safety, and casting technology. Which has been use for hundreds of years in the production of industrial products, can be use in conjunction with 3D printing for this purpose. Through a combination of design optimization, casting simulation, fatigue analysis and 3D printing technology, the automotive wheel bracket can reduce weight by up to 80%, increase strength several times, and improve driving performance.

Prototyping

3D printing is use for the production of experimental models and functional prototypes. Enabling rapid modification of design solutions and repeated mass iterations. While ensuring the quality of prototype product design, it greatly reduces the time required for product design and prototype development, and improves R&D efficiency.