Titanium TC4 Minimally Invasive Medical Electrodes

브랜드 이름: 선이정밀

인증: ISO90001,ISO13485

최소 주문 수량: 원피스

지불 조건: 신용장, 티/티

원산지: 광동, 중국

가격: 필요에 따라 견적

- 설명

- 문의

설명

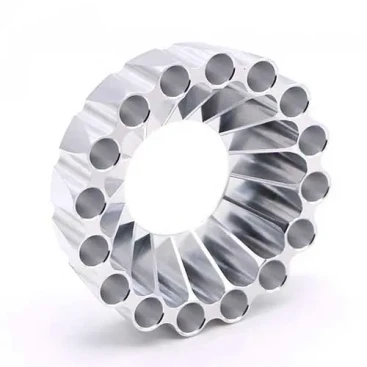

Titanium TC4 Minimally Invasive Medical Electrodes Introduction

제품: Minimally Invasive Medical Electrodes

Machining Type: Turning

Machining Precision: Finishing

Machining Material: Titanium Alloy TC4

Maximum Diameter: 4.0(mm)

Maximum Length: 28.0(mm)

용인: +-0.001mm

Surface roughness: Ra0.4

Processing materials: Almost any material can be processed. Stainless steel, titanium alloys, fusible alloys, copper and copper alloys, platinum-iridium alloys, ceramics, super-hard special steels, 등.

Certificates: SGS report available / ROHS and Reach compliant.

Main application areas: Minimally invasive medicine

Company Advantage:

1. High precision: the world’s top imported CNC machine tools. Ceramic bearing double spindle, scale guideway. Ensure high quality and high precision requirement of parts.

2. Modularity: Independent tooling system, modular machining design. Easy to cope with a variety of high-strength, high plasticity, difficult to process materials.

3. Systematization: the world’s advanced FANUC numerical control system, to ensure the stability and high efficiency of long time generation.

4. In-machine detection: machine to realize the machining process, the detection of key data and precision control, automatic adjustment of tool trajectory

If you need more information, please feel free to contact melody: +8618080315104