CNC Ultra Precision Machining of Hardware Parts

Jenama: Ketepatan Sun-Yee

Pensijilan: ISO90001,ISO13485

Kuantiti Pesanan Minimum: sekeping

Terma pembayaran: L/C, T/T

Tempat asal: GuangDong, China

harga: Sebutharga mengikut keperluan

- Penerangan

- Siasatan

Penerangan

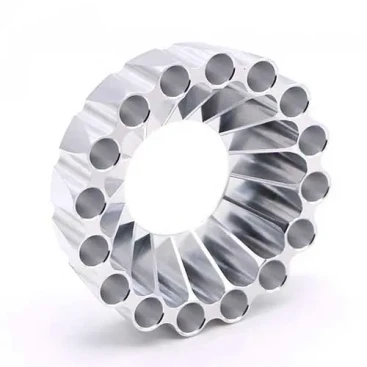

produk: CNC Ultra Precision Machining of vacuum hexahedron

Machining type: CNC machining center

Machining precision: Ultra-precision machining

Processing material: 304 316 stainless steel, carbon steel, aluminum, duplex steel, alloy steel, 20#.

Maximum diameter: 55 (mm)

Panjang maksimum: 55 (mm)

Ultra-precision machining: soft grit mechanical chemical polishing

Toleransi: 0.2

Scope of application: machinery parts, automobile manufacturing, new energy, aerospace factories, petrochemical industry, construction engineering, dan lain-lain.

Detail:

- Precision casting, quality assurance. Smooth surface without burrs, no obvious grinding line, high quality raw materials.

- Fine packaging, to prevent bumping. In order to prevent bumping during transportation, all of our products are bubble wrap packing.

- Finely polished surface with accurate dimensions. Precision mold with vulcanization process, small tolerance range and accurate size.

CNC ultra-precision machining applications

CNC precision hardware parts machining has become an indispensable part of the modern technology field. It is in a variety of industries, including automotive manufacturing, aeroangkasa, medical devices, electronic equipment and more.

- Automobile manufacturing industry:

Automobile is an important means of transportation for people to travel. There are thousands of precision parts. The fineness of auto parts directly affects the performance and safety of the car. In automobile manufacturing, CNC precision hardware parts machining can help manufacturers produce more accurate and durable automobile parts, such as engine parts, suspension system parts and so on. - Aeronautical and aerospace components:

CNC machining is widely used in aeronautical and aerospace components because of the high requirements for precision and strength in these areas. For example, aircraft engine blades and rocket engine nozzles can be produced by CNC machining. - Medical Device Manufacturing:

The production of medical devices requires a high level of precision and cleanliness. The use of CNC machining can ensure the quality of the product while increasing the production efficiency. For example, medical implants and prostheses can be produced by CNC machining. - Electronic equipment manufacturing:

Electronic equipment requires a high degree of precision and stability of components. By using CNC machining, the performance and quality of electronic products can be improved. For example, circuit boards and cell phone housings can be produced by CNC machining.