Anodizing Aluminum CNC Precision Parts Processing

Brand Name: Sun-Yee Tech

Certification: ISO90001,ISO13485

Minimum Order Quantity: One piece

Payment Terms: L/C, T/T

Place of Origin: GuangDong, China

Price: Quotation as required

- Description

- Inquiry

Description

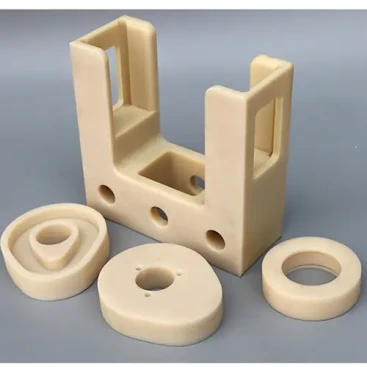

CNC Aluminum Parts Introduction

Products: CNC Aluminum Parts

Service: OEM/ODM

Tolerance: ±0.01mm

Surface Treatment: Anodizing

Samples: Accept for free

Material: Aluminum

Customize Service: Yes. We promise to keep the drawings strictly confidential.

Package: Carton/ plywood packing

Characteristics of anodized aluminum materials

1. Corrosion resistance

In fact, aluminum alloy is a corrosion-resistant metal, because aluminum is very active, especially easy to generate aluminum oxide by chemical reaction with oxygen in the air.

The aluminum oxide film is transparent, so the human eye is very difficult to see. This thin layer of alumina film just cut off the air so that the aluminum matrix is not oxidized. So it plays a role in corrosion resistance.

2. Abrasion resistance

Aluminum profile base material is particularly easy to be scratched and wear, aluminum alloy hardness after all can not be compared with steel.

And after anodic oxidation of industrial aluminum profile surface is very hard, high hardness of the oxide film. So the anodizing is very wear-resistant and not easy to scratch.

3. Insulation

The conductivity of aluminum is very good, but aluminum needs insulation in some occasions. Anodized aluminum oxide film is not conductive, so if you need to use insulation occasions need to be anodized.

CNC Machining Part Capabilities

Available Materials: Carbon Steel, Stainless Steel, Alloy Steel, Tool Steel, Titanium Alloy, Plastic, Aluminum, Copper, Brass, Bronze

Heat Treatment: Hardening, Nitriding, Carburizing, Laser Quenching, QPQ

Surface Finish: Zinc Plating, Chrome Plating, Chrome Plating, Passivation, Tin Plating, Silver Plating, Gold Plating, Anodizing, Hard Anodizing, PTFE Impregnated Hard Anodizing, Painting, Powder Coating, PTFE Coating, Brushing, Polishing

The CNC Aluminum Parts Cost

The cost of CNC machining is determined by material, part size, machine type, design complexity, quantity, etc. In addition, some additional expenses need to be included in the total cost, such as surface treatment or post-treatment fees for parts that require special surface treatment services, as well as transportation costs, especially for large quantities of parts or large-sized products.

If you want to know the price of the parts you need to process, contact us on our website.

Our quotation is completely free.