Carbon Steel Stamping Parts Surface coating treatment

Brand Name: Sun-Yee Precision

Certification: ISO90001,ISO13485

Minimum Order Quantity: One piece

Payment Terms: L/C, T/T

Place of Origin: GuangDong, China

Price: Quotation as required

- Description

- Inquiry

Description

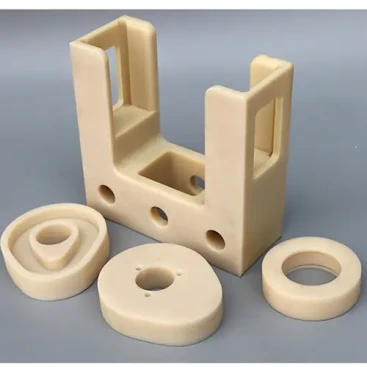

Carbon Steel Stamping Parts Introduction

This bespoke carbon steel parts uses a stamping process to press out 50mm carbon steel sheet. The surface coating treatment enhances the wear and corrosion resistance of the carbon steel material. The stamping process allows for cost-effective and efficient mass production of metal parts for maximum economic efficiency.

Contact our team of experts to get a quick start on your custom sheet metal stamping project.

Get an online manufacturer’s quote and a full range of technical support services.

Material: Q235B

Machining thickness: 50 (mm)

Weight: 0.045 (kg)

Tolerance: 0.1mm

Surface treatment: surface coating treatment

Surface treatment

We all know that carbon steel products and stainless steel compared to one of the obvious disadvantages is easy to rust, not as durable as stainless steel as new. And in order to make carbon steel products are not so easy to rust, will be how to deal with it?

①Hot-dip galvanizing

Hot-dip galvanizing is one of the most effective ways to remove rust. After removing the rust, the steel parts are immersed in the melted zinc solution at about 500℃, so that the zinc layer is attached to the surface of the steel parts. Of course, this treatment is more expensive.

②Chrome, nickel, and zinc plating

The cost is not so high, generally such as chromium plating, nickel, zinc and so on. Among them, zinc plating is the more conventional and frequently used surface treatment. It should be noted that the galvanization here refers to cold galvanization (i.e., electro-galvanization), which is different from the hot-dip galvanization above, and the thickness is thinner than hot-dip galvanization, and the corrosion resistance is also worse.

If there is no need to prevent rust for a long time – this temporary rust prevention is generally the use of antirust oil or antirust liquid. Among them, the rust prevention time of the rust prevention oil is a little longer than the latter, but the rust prevention liquid to do spraying if you do not need to clean, can be sprayed directly.