CNC 5-axis Machining of Titanium Impeller

Brand Name: Sun-Yee Precision

Certification: ISO90001,ISO13485

Minimum Order Quantity: One piece

Payment Terms: L/C, T/T

Place of Origin: GuangDong, China

Price: Quotation as required

- Description

- Inquiry

Description

Titanium Impeller Introduction

Product: 5-axis CNC machining of titanium impeller

Material: titanium alloy

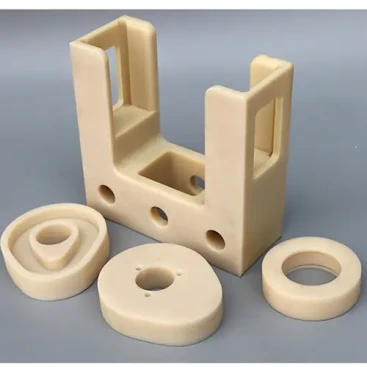

Optional production materials: aluminum alloy, plastic, copper, zinc alloy and other materials

Surface treatment: oxidation, hard oxidation, oil spraying, polishing, PC transparent, plating, laser engraving, silk screen printing, etc.

Product shape: according to the customer’s sample or drawing requirements, etc. production

Packaging: according to customer’s needs or requirements.

Feature:

Professional level: high-quality materials, in strict accordance with technical requirements, to ensure product strength and precision.

Strict quality control: adopt strict testing equipment, strict testing of product dimensions, to ensure product standards

Support customization: support non-standard customization, customized to the drawing, high precision

Exquisite craftsmanship: smooth surface, strong and reliable, uniform force, excellent quality

Case

The following are two custom impellers made of TC4 titanium alloy, with a diameter of 200m and a height of 100m.

Titanium alloy compared to aluminum alloy, stainless steel material is harder, not easy to process. Moreover, the impeller structure is special. The blade is extremely thin, the base between the blade and the blade is required to be curved surface, which is very easy to be deformed during processing. And small rounded corner between the matrix and blade smooth transfer, easy to produce stress concentration, cracks in the work. It is also not easy to turn molding from bar material to bar embryo. The tip part of the blade is a space surface composed of different radii of curvature, the related dimensional accuracy requirements are high, machining difficulty, is one of the difficulties in the manufacture of parts.

After receiving the order, SUN-YEE TECH made full use of the CNC equipment for the processing difficulties of the parts. The use of software for modeling, programming, repeated debugging, test cutting, optimize the CNC program to do the initial preparatory work. Then next, develop the process flow, impeller machining process divide into impeller roughing, impeller semi-finishing, impeller finishing and several other machining strategies. The purpose of roughing is to quickly and efficiently get rid of the blank allowance, but also the most representative of the impeller processing efficiency strategy. Semi-finish machining is to make the blade face even, and make corresponding preparation for the next finish machining. Finishing lies in how to obtain a very good surface quality, in the choice of tools, machine speed and feed with a great relationship.

Our Advantage

1. Factory self-operated, integrating generation, processing and trade, specializing in precision spare parts processing.

2. Reliable technology, difficult functions and structures can quickly process and molded to maintain accurate originality.

3. short processing cycle, fast delivery to ensure delivery within the specified time.

4. assured quality, materials, CNC machining precision up to 0.005mm or less.