High-Volume CNC Machining Process

- Description

- Inquiry

Description

High-Volume CNC Machining Process cnc machining service supplier

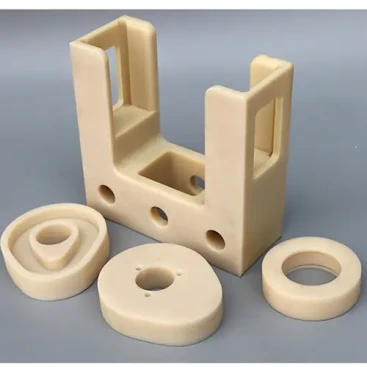

High-volume CNC machining meets the demands of various industries that require mass production of precise components. It has become the essential method for transforming raw materials into finished products with remarkable regularity. Process automation ensures continuous and rapid production without requiring constant human intervention. This efficiency translates into a competitive advantage for companies that allows them to meet market demands and stay ahead in dynamic industries.

At SUN-YEE, high-volume CNC machining is the essential solution for versatile and efficient manufacturing. With a wide range of materials and advanced technologies at our disposal, we can meet the demands of large-scale production while maintaining the high quality standards required in today’s competitive market. Our expertise in CNC machining, coupled with our automation and multi-axis capabilities, allows us to deliver top-notch components across various industries, ensuring our customers’ success and satisfaction.

SUN-YEE’S Advantage

1.SUN-YEE’s high-volume CNC machining process is a well-organized approach that ensures efficiency, precision and consistent quality throughout the production cycle. This process begins with a thorough project assessment, where we work closely with our clients to understand their specific needs, technical specifications and desired outcomes. Once the design is finalize, our team of qualified programmers takes over. We use advanced computer-aided manufacturing (CAM) software to convert designs into machine-readable code. Once the program is ready, we continue to select the appropriate tooling for the CNC machine. Our extensive inventory of cutting tools, drill bits, milling cutters ,and other necessary tools. Ensures that we are equipped to handle a wide variety of materials and component geometries.

2.The full-scale production phase begins after successful tooling and setup. Our state-of-the-art CNC machines, operated by trained technicians, work tirelessly to manufacture components according to programmed instructions. The automated nature of CNC machining allows for continuous production, significantly reducing lead times for high volume orders. At every stage of the high-volume CNC machining process, we maintain a robust quality control and quality assurance system. Our team performs extensive testing and inspection to verify component accuracy and functionality. Any deviations or discrepancies are immediately correcte and. If necessary, corrective measures are taken to maintain the highest level of quality.

high precision cnc machining services, machining aerospace parts, precision machining sheet metal precision cnc machine shop, custom precision machining, aerospace machined parts,turned components manufacturer air craft cnc machining,cnc machining service supplier.