PEEK CNC Machining Parts Automobile Parts

Brand Name: Sun-Yee Precision

Certification: ISO90001,ISO13485

Minimum Order Quantity: One piece

Payment Terms: L/C, T/T

Place of Origin: GuangDong, Китай

Price: Quotation as required

- Description

- Inquiry

Description

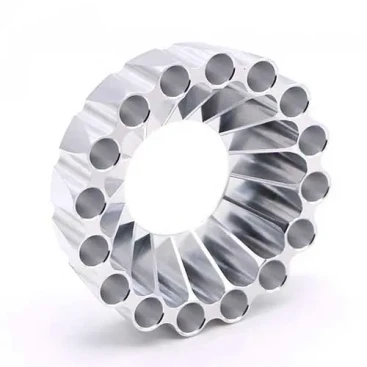

PEEK CNC Machining Parts Automobile Parts Introduction

Продукт: PEEK CNC Machining Parts

Material: PEEK

Production process: CNC machining

Tolerance: 0.02мм

Maximum diameter: 500 (мм)

Maximum length: 800 (мм)

PEEK material processing

Reasonable planning of the machining process and parameters can effectively improve the success rate of processing PEEK parts and the performance of the final product. When processing PEEK (polyether ether ketone), a high-performance engineering plastics, you need to pay attention to the following key points to ensure processing quality and efficiency:

- Choosing the right machining tool: Wear-resistant, high-temperature resistant tool materials should be use. Such as fine-grained C-2 carbide or PCD (polycrystalline diamond) inserts. Tool edge geometry and cutting angles need to be appropriate, positive geometry tools are recommended. And a grounded perimeter is considered to avoid static buildup during machining.

- For reinforced PEEK (e.g., with glass or carbon fibers), the tool should be more wear-resistant because the material is more abrasive. Control machining parameters: Optimize feed rate, RPM and depth of cut to reduce heat generation and avoid thermal deformation or thermal cracking of the material. Good temperature control should maintain during machining to avoid localized overheating, as PEEK has a higher coefficient of thermal expansion than metal.

- Pre-treatment and drying: Before injection molding process, PEEK material needs to dry sufficiently to remove moisture to prevent bubbles or silver lines during processing

- Cleaning and Maintenance: Regularly clean processing equipment and tools to avoid the accumulation of residual PEEK material that could affect the quality of the next process. Use appropriate lubricants and coolants to maintain tool sharpness and improve machining efficiency while protecting PEEK surface quality.

- Equipment selection: Choose high-performance equipment suitable for processing PEEK, such as high-speed machining centers, in order to achieve high-precision and high-efficiency machining.

- Machining strategy: For thin-walled or complex shaped parts, use step-by-step machining or light cutting for many times to minimize material deformation.