Titanium Accessories TC4 Alloy Titanium Ball

Brand Name: Sun-Yee TECH

Certification: ISO90001,ISO13485

Minimum Order Quantity: One piece

Payment Terms: L/C, T/T

Place of Origin: GuangDong, Китай

Price: Quotation as required

- Description

- Inquiry

Description

Detail

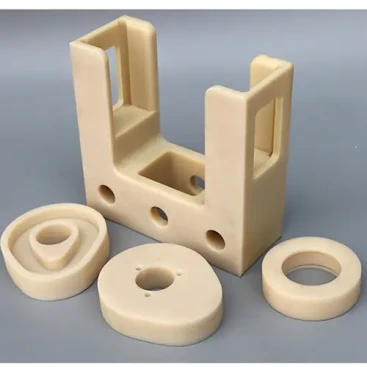

Продукт: Titanium Accessories Ball

Material: TC4, TA1, TA2, TA9, TA10, TC11

Advantages of titanium processing parts: good corrosion resistance, light density, high strength

Melting point: (1668±10)°C

Density: 4.5 G/CM3

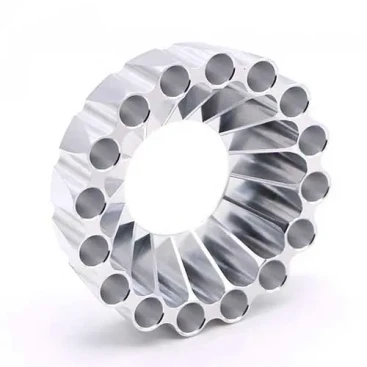

Production process: milling, turning, бурение, и т. д..

Surface treatment: polishing, sandblasting, анодирование, и т. д..

Tolerance:Dimension tolerance, shape and position tolerance, и т. д..

Suitable Environment:High temperature, corrosion, и т. д..

Application:

- Aerospace field: used to manufacture aircraft structural parts, engine parts, missile parts, и т. д..

- Medical equipment field: for the manufacture of artificial joints, implants, surgical instruments and so on.

- Chemical industry: used in the manufacture of corrosion-resistant containers, reactors, heat exchangers and so on.

- Electronic product field: used in the manufacture of cell phone shells, computer parts, electronic equipment shells, и т. д..

- Automotive industry: used to manufacture automotive parts, exhaust systems, wheel hubs, и т. д.. Sporting goods: used to manufacture high-end high-performance sports equipment, such as golf clubs, bicycle frames and so on.

Advantage of manufacturers: commonly used specifications of titanium machining parts in stock, more embryo material, short processing cycle, price activation Win low, excellent quality, welcome to consult and negotiate.

Titanium Accessories Features:

1. High strength and light weight

Titanium alloy has a very high specific strength. This means that it is only 60% of the weight of steel while maintaining high strength. This makes titanium alloys ideal for the manufacture of structural parts for aircraft, rockets and missiles, и т. д..

2. Excellent corrosion resistance

Titanium alloys exhibit excellent corrosion resistance in humid atmospheric and seawater media, and are particularly resistant to pitting, acid and stress corrosion. This makes it very useful in the medical field (e.g., for the fabrication of artificial joints and dental appliances), as these applications often require use in corrosive environments.

3. High temperature resistance

Titanium alloy can maintain its strength and properties at higher temperatures. This makes it suitable for high-temperature environments or applications requiring high-temperature resistance, such as aircraft engine components.

4. Thermal conductivity and modulus of elasticity

Titanium alloys have poor thermal conductivity. This can lead to higher cutting temperatures and friction during machining. Also, it has a low modulus of elasticity. This may lead to easy deformation during stress.

5. Machining difficulty

Due to its poor thermal conductivity and high hardness, titanium alloys are relatively difficult to machine. This includes the need to use special tools and machining techniques, as well as the possible need to machine at lower temperatures to minimize tool wear.

6. Chemical activity

Titanium alloys are susceptible to chemical reactions with atmospheric oxygen, nitrogen, и т. д., which may affect their properties and surface finish. Поэтому, when applying titanium alloys, appropriate surface treatments are often required to protect it from corrosion.