Machined Aluminum Parts Precision CNC Machining Parts

ชื่อแบรนด์: ซุนยีพรีซิชั่น

การรับรอง: ISO90001,ISO13485

ปริมาณการสั่งซื้อขั้นต่ำ: หนึ่งชิ้น

เงื่อนไขการชำระเงิน: แอล/ซี, ที/ที

สถานที่กำเนิด: กวางตุ้ง, จีน

ราคา: ใบเสนอราคาตามที่ต้องการ

- คำอธิบาย

- สอบถามรายละเอียดเพิ่มเติม

คำอธิบาย

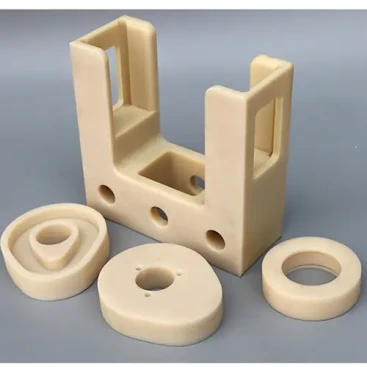

Machined Aluminum Parts Precision CNC Machining Parts Introduction

Products: machined aluminum parts

Minimum machinable wall thickness: 0.01

Processing material: อลูมิเนียม

Processing form: as the drawing, ขั้นตอน,STP,GIS,CAD,PDF,สวทช,DXF etc or samples format file pr sample.

Surface treatment process: anodized

Type of machining: Milling

Production period: 1-3 วัน

Tolerance and Surface Roughness: +/-0.002 – 0.01มม ,Ra 0.1~3.2

Applications of machined aluminum parts

1. Automobile manufacturing

Aluminum alloys are widely used in automotive parts due to their excellent strength-to-weight ratio. Aluminum alloy parts are mainly used in engine cylinder block, cylinder head, piston, intake manifold, rocker arm, engine mounting bracket, air compressor connecting rod, actuator housing, clutch housing, wheels, brake parts, handles, and cowl shell parts.

2. Aerospace industry

Aluminum is widely use in aircraft, mainly as structural components. Aluminum alloy is the main structural material for aircraft, such as skins, frames, propellers, fuel tanks, wall panels and landing gear struts, because of its high specific strength and good forming and machining properties.

3. shipbuilding industry

From the superstructure of large surface ships, the construction of thousands of tons of all-aluminum marine research vessels, ocean-going merchant ships and passenger ships, to hydrofoils, hovercrafts, passenger ferries, catamaran passenger ships, traffic boats, landing craft, and other types of high-speed passenger ships and military speedboats, a large number of deformed aluminum alloys are use. Casting aluminum alloys are mainly use for pumps, pistons, outfittings and rainwater mine shells and other components.

เกี่ยวกับเรา:

We provide customers with product machining services from sampling, trial fitting improvement, mass production post-processing until product delivery.

After more than 10 years of machining experience, we have formed a complete manufacturing chain, customers only need to provide drawings or documents, we can realize the manufacturing. Every new project we undertake, we will design a set of reasonable product process from material source to machining production to surface treatment to present good products to customers.

Welcome to send inquiry to contact us!