How to choose stainless steel- Common classification

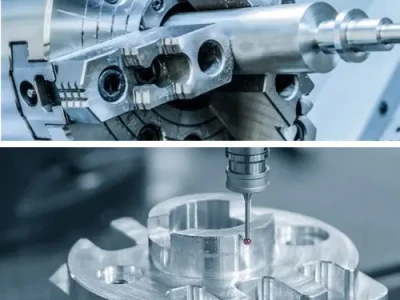

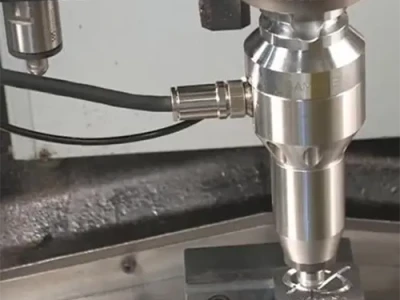

How to choose stainless steel- The most complete knowledge of stainless steel of 201、202、301、302、304 ! Stainless steel is one of the most common steel materials contacted in precision parts manufacturing. So, knowledge of stainless steel helps to help people better grasp how to choose stainless steel. Common classification Common stainless steels are usually classified into three categories according to their metallurgical organization: austenitic...