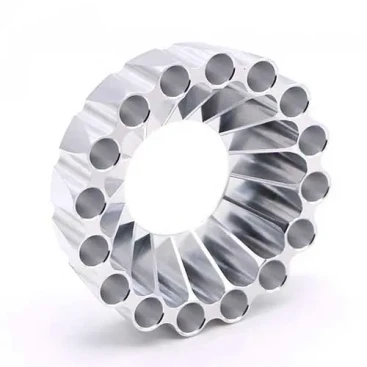

Các bộ phận kim loại tiện và phay CNC

- Vật liệu: Thau, aluminum

- Size: /

- Process: CNC turning, CNC milling

- Xử lý bề mặt: machined surface

- Sự miêu tả

- Cuộc điều tra

Sự miêu tả

What Types of Brass and Aluminum are Suitable for CNC Turning and Milling?

When selecting brass and aluminum for CNC turning and milling, it’s important to consider the specific properties of each alloy and how they align with your project requirements, such as machinability, strength, corrosion resistance, and intended application. Here are some commonly used brass and aluminum alloys for CNC machining:

Brass Alloys

C360 (Free-Cutting Brass):

Properties: High machinability, good strength, corrosion resistance, and excellent wear resistance.

Ứng dụng: Precision components, fittings, van, and various decorative parts.

C385 (Architectural Bronze):

Properties: Good machinability, excellent corrosion resistance, and good mechanical properties.

Ứng dụng: Hardware, architectural applications, and decorative components.

C464 (Naval Brass):

Properties: Good strength, excellent corrosion resistance (especially in marine environments), and good wear resistance.

Ứng dụng: Marine hardware, propeller shafts, and other maritime components.

Aluminum Alloys

6061 Nhôm:

Properties: Excellent machinability, good strength, good corrosion resistance, and good weldability.

Ứng dụng: Structural components, automotive parts, and aerospace applications.

7075 Nhôm:

Properties: High strength, good fatigue resistance, and good machinability, but lower corrosion resistance compared to 6061.

Ứng dụng: Aerospace and military applications, high-stress components.

2024 Nhôm:

Properties: High strength, good fatigue resistance, and good machinability, but poor corrosion resistance.

Ứng dụng: Aerospace structures, military applications, and high-performance components.

5083 Nhôm:

Properties: Excellent corrosion resistance, good weldability, and moderate strength.

Ứng dụng: Marine applications, pressure vessels, and transportation equipment.

5052 Nhôm:

Properties: Good formability, good corrosion resistance, and moderate strength.

Ứng dụng: Sheet metal work, marine applications, and transportation industry.

Selection Criteria

When choosing the right alloy, consider the following factors:

Machinability: Ease of cutting, shaping, and drilling.

Strength: Required mechanical strength for the application.

Corrosion Resistance: Need for resistance to environmental factors such as moisture, chemicals, or saltwater.

Finish Quality: Desired surface finish and whether post-machining treatments are necessary.

Cost: Budget constraints and material cost.

These alloys are commonly used in CNC turning and milling due to their favorable properties for machining and the wide range of applications they can serve.

SUN-YEE can providing you CNC turning and milling services with metal materials including brass, aluminum, stainless steel etc.. Any surface treatments can be machined as you required, please feel free to contact us when you need.