3D印花灯罩壳

品牌名称: 新义精密

认证: ISO90001,ISO13485

最小订购量: 一件

付款条件: 信用证, 电汇

产地: 粤, 中国

价格: 按要求报价

- 描述

- 询问

描述

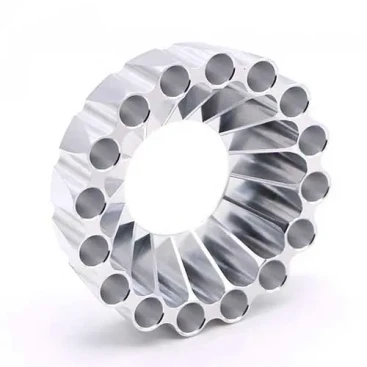

3D printed lampshade shell introduction

产品: 3D printed lampshade shell

材料: PLA+ABS

尺寸: 80/100/120/150/180/200/300毫米. Customizable upon request

Shape: 根据客户定制’ needs

Application: 家, 灯光, 装饰

特征:

1. safe, non-toxic, odorless, high temperature resistance, good antioxidant properties

2. the material has good light transmittance, soft light and eye protection.

3. 3D printing real restore planet surface texture. DIY free combination with. Create your own exclusive lighting environment

3D Printing Materials

1. Imported resin

White color, recommended for making parts with fine details, good toughness and high strength.

2. Transparent Resin

With the surface smoothness and detail of white photosensitive resin, the parts are almost colorless and look more like real transparent plastic.

3. 尼龙

High temperature resistance, good toughness and strength, suitable for electrical appliances and power tools.

4. Soft rubber

Heat-resistant, cold-resistant, good elasticity with a certain degree of carrying strength and tearing.

5. Red wax

Suitable for complex shapes, thin-walled precision parts, 良好的耐腐蚀性, can be surface treatment.

6. Aluminum Alloy

Low density, high specific strength, small limitation by part structure design.

7. Zinc Alloy

Suitable for complex shapes and thin-walled precision parts, with good corrosion resistance and a wide range of surface treatments available.

8. ABS

Good strength, a variety of colors are available, the surface has a layer pattern, the price is lower.

Advantages of 3D printing:

1. Increased productivity and fast turnaround time

2. No need for molds, effective control of manufacturing costs

3. Personalized design and variety of product shapes

4. Integrated product molding manufacturing, high precision production