- 描述

- 询问

描述

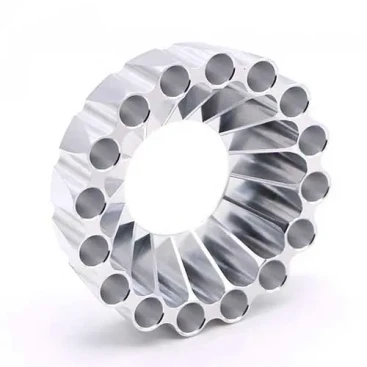

Stainless steel metal injection molding parts introduction

产品: 不锈钢金属注塑件

Production process: Metal powder injection molding (MIM)

材料: 不锈钢, iron base material, copper base material, nickel alloy, 铝合金, tungsten alloy, 钛合金, cemented carbide, magnetic material, KOVAR alloy and so on.

Stainless steel: 304L, 316L, 17-4PH, 420, 440C, SKD11, 310 and so on.

Iron-based materials: pure iron 1010, FE2NI, FE4NI, FE8NI, FE50NI, FE8ONI, 4605, 8620, ETC.

Tungsten alloy: tungsten carbide, tungsten-nickel-iron, tungsten-nickel-copper, tungsten-copper, ETC.

Titanium alloy: TA1, TA2, TC4, ETC.

Precision range: five thousandths of the size tolerance.

Size range: 0.1mm-300mm

Weight range: 0.1g-1000g

Customization: non-standard customization, according to drawings or samples

Application areas: locks, 3C, equipment, smart wearable, 医疗的, 汽车, electrical appliances, 通讯, clocks and watches, ETC.

MIM Machining Advantage:

1. High degree of design freedom

2. Wide selection of raw materials

3. High mechanical strength

4. Good appearance

5. High dimensional accuracy

6. Small tolerances

7. Fast mass production

8. High utilization of raw materials