不锈钢非标精密铸造汽车配件

品牌名称: 新义精密

认证: ISO90001,ISO13485

最小订购量: 一件

付款条件: 信用证, 电汇

产地: 粤, 中国

价格: 按要求报价

- 描述

- 询问

描述

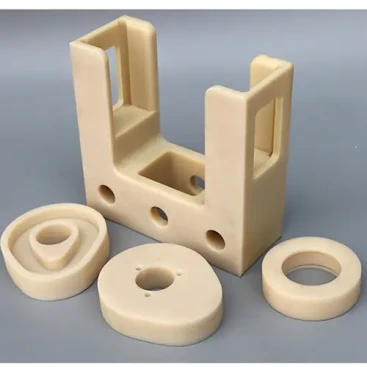

Precision Casting Auto Parts Introduction

产品: precision casting auto parts

材料: 不锈钢

尺寸: Customized on demand

Features: 高硬度, 不易变形, not easy to wear

Detail:

Selection of materials by heart Strict quality inspection

Stainless steel 201/304/316L and other materials casting processing, on-site inspection

Surface treatment Support processing

Casting surface smooth, 支持抛光加工, 刷涂和抛光, 电解, 喷涂等.

Fast sample delivery on time

Diversified specifications, 支持来图来样定制, 快速运输, 可以加急订购!

More information, please contact SUN-YEE TECH!

Stainless steel casting process features

1. Stainless steel precision casting in the production process because of its transition band size is small, which will make its mechanical properties. Can be effective to a certain extent to meet its mobility as well as not form a bright crystallization prevail, the general temperature of 715 ~ 740 ℃

2. The cracking tendency of round ingots cast by this process is relatively low. This can to a certain extent effectively ensure that its alloy has its good exhaustion and shrinkage capacity. When in use, it can effectively create its order close to the conditions, effectively improve its density. The casting temperature is generally high.

3. The use of stainless steel investment casting temperature to effectively ensure that the melt will have its good mobility in the process of reinjection. Selection of temperature should be based on the distance of reinjection, reinjection process cooling conditions, alloy, specifications, flow and other factors to determine.

4. The production temperature can to a certain extent to ensure that the melt in the process of reinjection will have good fluidity. Equipment in the process of selecting its casting temperature needs to be based on the distance of the injection and the injection process of cooling conditions and other factors to determine.