不锈钢传感器外壳 CNC 加工

品牌名称: 新义精密

认证: ISO90001,ISO13485

最小订购量: 一件

付款条件: 信用证, 电汇

产地: 粤, 中国

价格: 按要求报价

- 描述

- 询问

描述

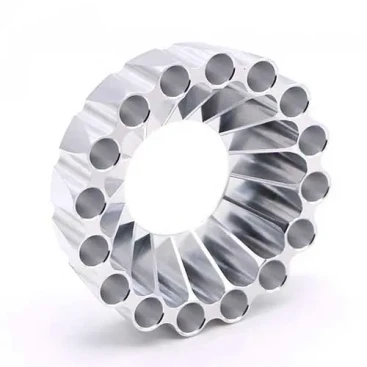

Stainless steel sensor housing introduction

产品: Stainless steel sensor housing

Processing method: CNC processing

材料: 不锈钢 304/ 316

规格: 本样品规格为30*25*40mm, can be customized according to the requirements

Application: 传感器零件, 机械零件, 食品温度计制造商.

特征:

Stainless steel material with high corrosion resistance

数控加工, 加工精度高, 光滑的表面

Customized on demand, 免费样品

Advantages of parts made of stainless steel:

Stainless steel parts have a variety of advantages, mainly including:

Corrosion resistance: stainless steel is not easy to rust. In particular, austenitic stainless steel, which contains chromium and nickel, is not only resistant to rust but also highly heat resistant. This allows stainless steel to maintain its performance and integrity in a wide range of environments.

High Strength and Stiffness: Stainless steel has a high modulus of elasticity and allowable stress, making it less likely to bend or deform. This makes stainless steel ideal for the manufacture of mechanical components that require a high degree of strength and stiffness.

Cleaning and Maintenance: Stainless steel has a smooth surface that does not easily accumulate dirt and is easy to clean. It also has excellent chemical resistance, making it suitable for use in applications requiring strict hygiene standards, such as food processing and medical equipment.

Cost-effectiveness: Stainless steel is typically less costly than some alternative materials. It also reduces the need for maintenance and repairs, thereby lowering long-term operating costs.

Wide range of applications: Stainless steel is used in a wide range of applications such as construction, 汽车, food processing and many other areas due to its durability and aesthetics.

SUN-YEE TECH specializes in the manufacture of non-standard spare parts. We have CNC machining center, 3D printing center, injection molding center. We specialize in precision and ultra-precision micro-parts processing. More information welcome to contact us!